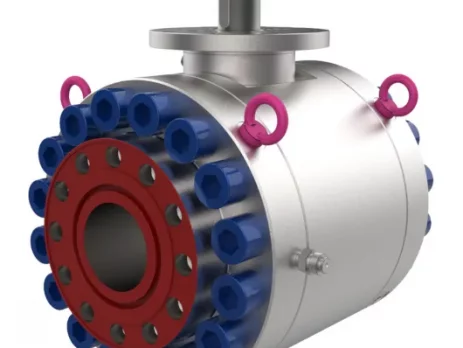

PRODUCT DETAILS

High pressure ball valves are products that can show the necessary resistance against the pressure values of the fluid passing through it. In fact, each valve acts as a pressure vessel element on the line in which it is located. In high pressure lines; the valve body and the valve elements inside must be able to withstand these pressure values. If the valve elements are positioned incorrectly or if the valve elements are not selected correctly; the valve elements may permanently change shape and create leakage.

In order to increase the performance of high pressure ball valve products and to ensure safer operations, special engineering solutions are applied to HG-Stahl ball valve products that minimize negative effects such as cavitation, abrasion and vibration. Turbulence created by the fluid passing through the ball valve, especially at high speed and pressure, can lead to wear, erosion and loss of performance over time. In order to prevent such problems, HG-Stahl uses optimized internal passageways in its high pressure ball valve products that ensure smooth flow routing. Thus, the turbulence created by the fluid is minimized, both extending valve life and reducing maintenance requirements. At the same time, these special designs increase the safety of the system by controlling sudden pressure fluctuations that may occur during operation in high pressure lines.

In systems operating under high temperatures, ball valve materials can be subject to thermal expansion. To overcome this, HG-Stahl uses ball valve elements that can tolerate thermal expansion and work with different material combinations. In this way, HG-Stahl ball valve products maintain valve performance and sealing properties even in systems operating under both high temperature and high pressure.

HG-Stahl High Pressure Ball Valves are specially designed and manufactured. At specific pressure and temperature values; the valves are simulated before design by finite element method and the correct choices are made according to the material yield and rupture strength.

In ball valves operating at high pressure, metal seated ball valves can be preferred or soft sealing elements such as PTFE, PEEK, Delrin, Nylon can be used depending on the pressure class and size of the valve.

In cases where oil can pass through high pressure valves, carbon steel can be used as valve material, while stainless type corrosion resistant materials are preferred for valves that pass water or similar fluids. In both types of products; depending on your demand; HG-Stahl can offer you the most suitable one from its own designed and manufactured valves as well as the products of European, UK or Chinese origin that it represents.

High Pressure Ball Valves; floating, guided (trunnion), full bore or half bore; can be produced in one, two or three piece form. Design standards are EN-12516, ISO 17292, ANSI B16.34, API6D, while face to face standards are EN558, ANSI B16.10 or special dimension requests. In connection flange; we can help with EN 1092-1 & EN 1092-2, ANSI B16.5, B16.47 standards. Connection standard for valve top flange is ISO 5211. The test standard can be EN 12266, API598 or ISO 5208. Fire safety is ensured by designs according to API607, API6FA and ISO 10497 standards.

Especially in the field of water hydraulics, Tiefenbach products are the world leader and can support many special projects.